- 4.7

FEATURES

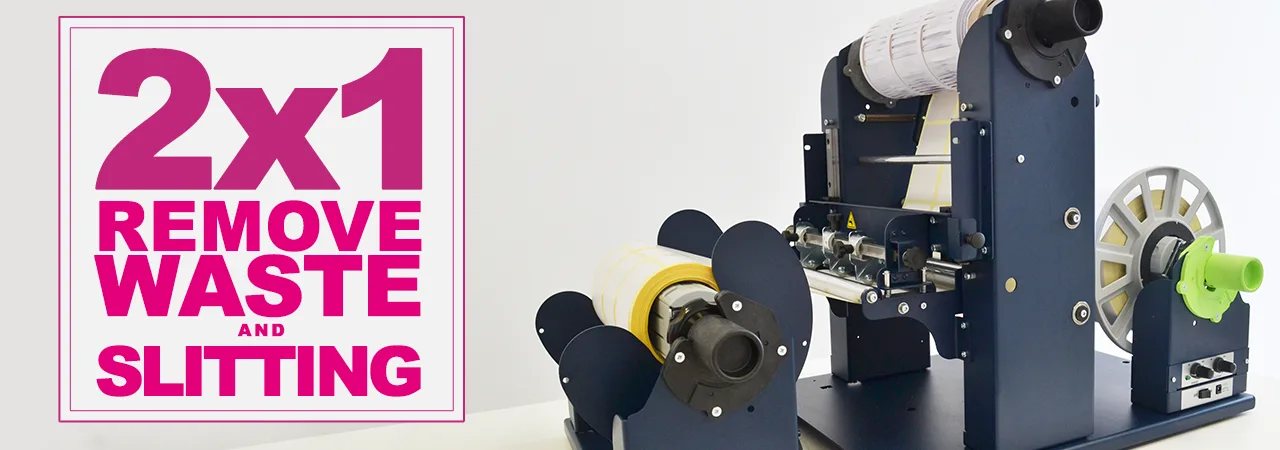

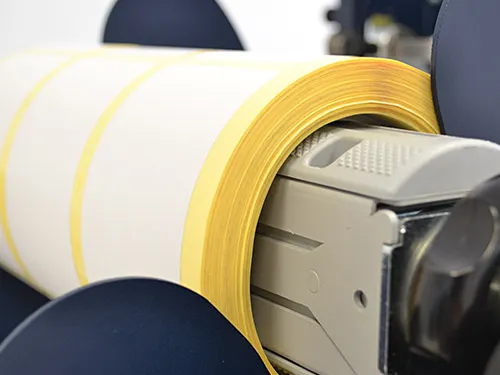

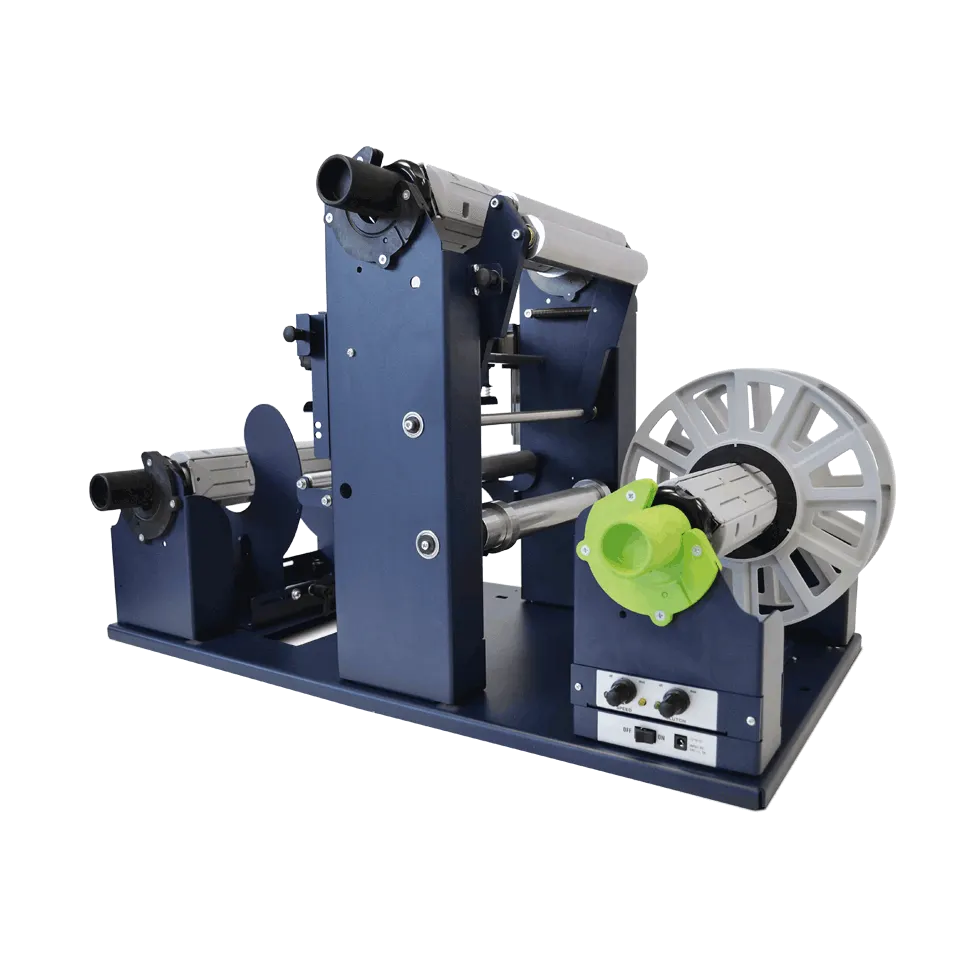

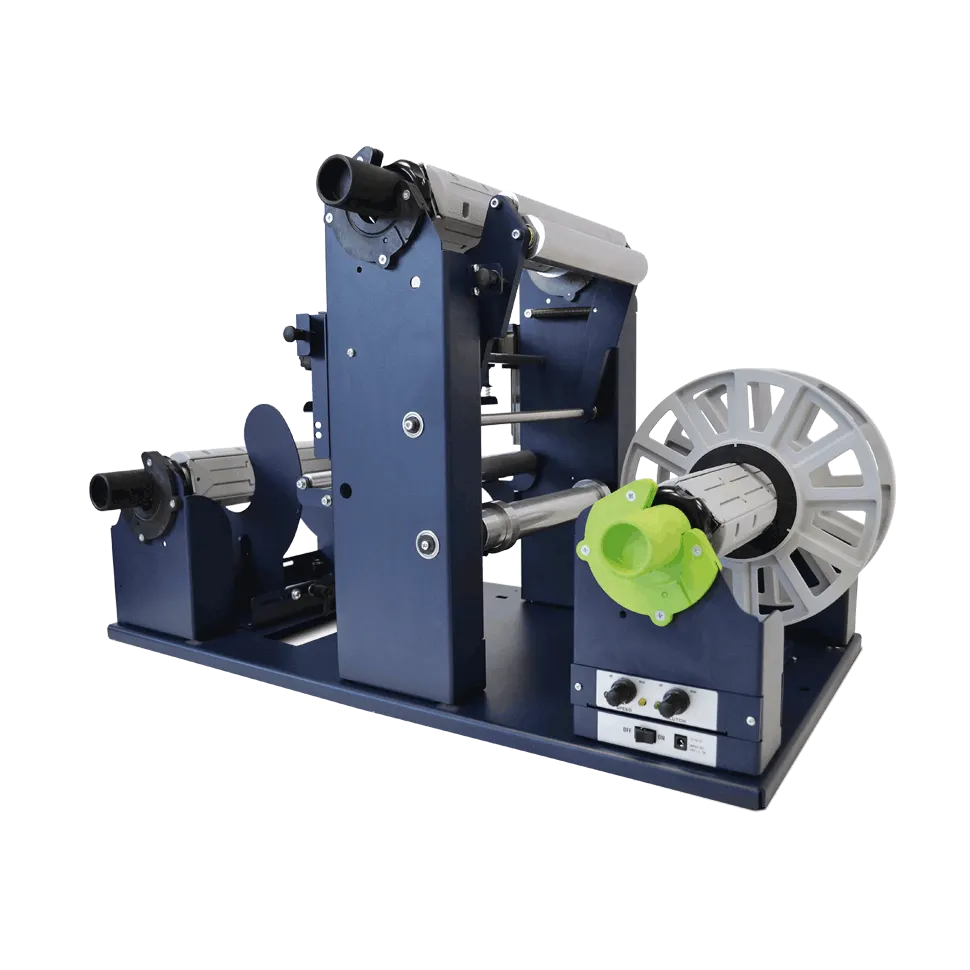

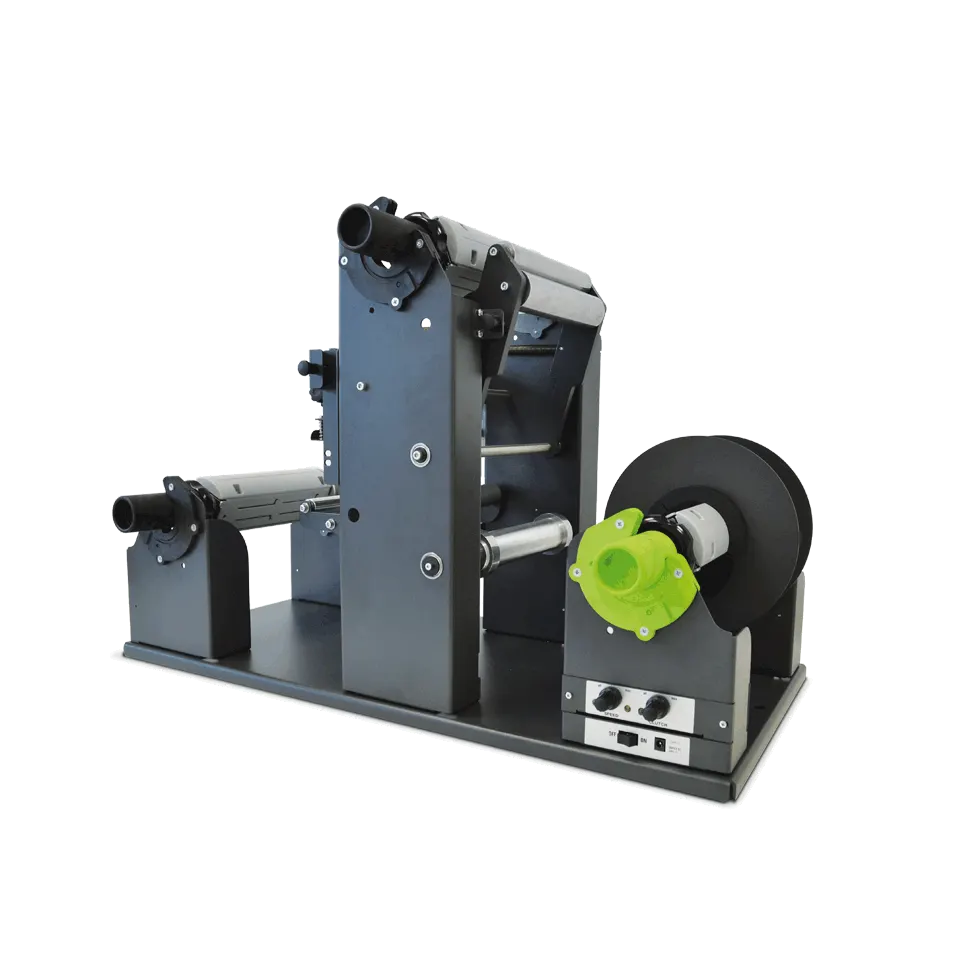

The matrix removers give the user the ability to remove the waste material from printed or blank pre die-cut rolls of labels up to 225mm (8.86”) wide onto 3” cardboard core and having an outside diameter up to 250mm (9.84”). The finished labels will be rewinded face out only.

Perfect full bleed labels can be achieved on pre die cut media after the waste material is removed.

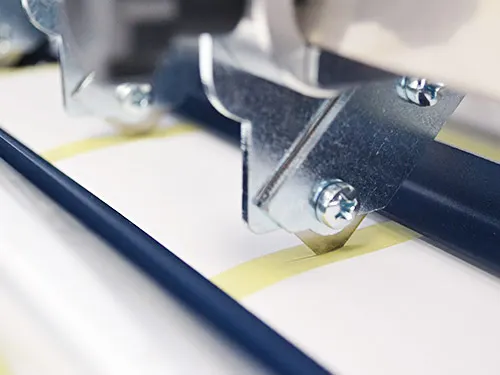

Available in two versions, the narrower MCH100MTX17 allows media width up to 170mm (6.69”) while the MCH100MTX25 up to 225mm (8.86”). Both units include the slitter module.

The production of edge-to-edge printed labels on roll will become extremely easy and quick.

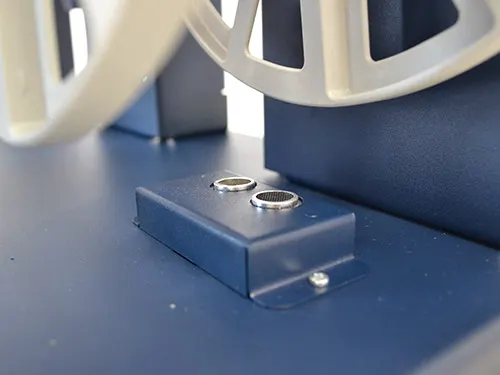

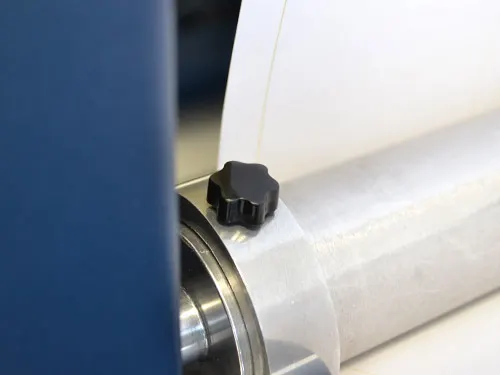

The unit is equipped with an electronic clutch system that allows the user to set manually the main media tension depending on pre die-cut label’s path complexity and type of media. During the operation the ultrasonic sensors together with the electronic controls will make sure to keep constant the tension on the media despite the roll diameter variation.

Brochure | User Manual MCH100MTX17 | User Manual MCH100MTX25 | User Manual MCH100MTX35 |

Workflow optimization

Time Free is the the main benefit of this Matrix Remover & Slitter. Being an offline solution where load the printed pre die-cut roll, each job will be completed without any interruption which could have occurred during the printing process in case it was in-line with the printer.

| MCH100MTX35 | MCH100MTX25 | MCH100MTX17 | |

|---|---|---|---|

|

|

|

|

| Input / Output Roll Diameter | 250mm (10”) | 250mm (10”) | 200mm (7.87”) |

| Maximum media width | 350mm (13.77”) | 225mm (8.86”) | 170mm (6.69”) |

| Minimum slitting width | 19mm (0.75”) | 19mm (0.75”) | 19mm (0.75”) |

| Number of slitting blades | up to 12 (6 blades included) |

up to 8 (4 blades included) |

up to 6 (3 blades included) |

| Power requirements | 100/240VAC - 5A at 24V power supply |

100/240VAC - 5A at 24V power supply |

100/240VAC - 2.5A at 24V power supply |

| Roll core size | 76 mm (3”) | ||

| Agency Certifications | CE, RoHS | ||

| MODELS | LENGTH | WIDTH | HEIGHT |

|---|---|---|---|

| MCH100MTX35 | 89cm (35.03") | 65cm (25.59") | 54cm (21.25") |

| MCH100MTX25 | 89cm (35.03") | 50cm (19.68") | 54cm (21.25") |

| MCH100MTX17 | 79cm (31.10") | 45cm (17.71") | 53cm (20.86") |

VIDEO