- 4.7

FEATURES

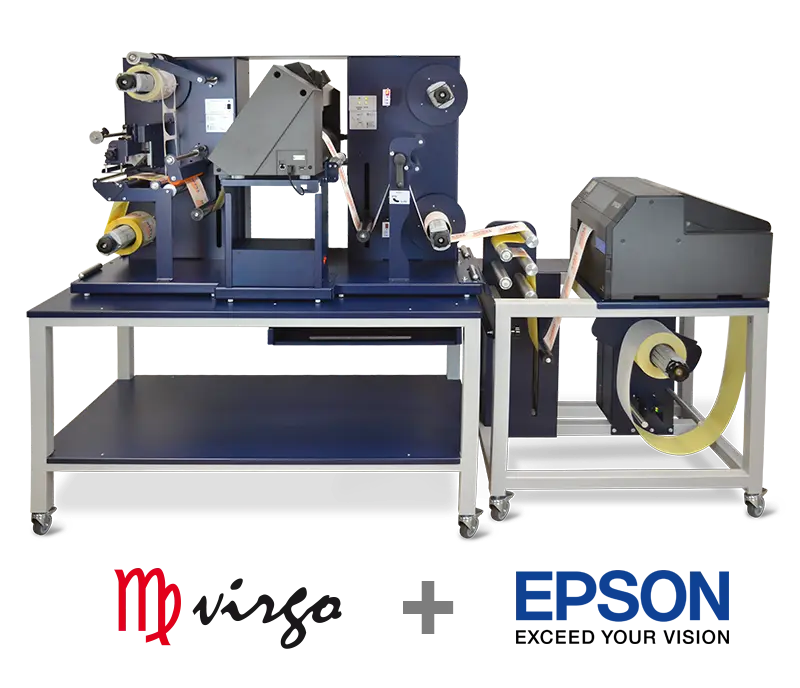

Virgo is a compact destop finishing system that unwinds, laminates labels for durability, digitally die cuts, removes excess label material around each die-cut shape, slit, and rewinds offering you everything to professionally cut and finish labels.

The system provides a very accurate label finishing solution using cutting plotter technology with reduced dimensions.This allows you to cut different types of materials and shapes on the fly without the added cost of dies.

The unit is also equipped with a cutter management tool that works in tandem with a camera forming an integrated optical black-mark registration system providing cutting speed optimization and avoiding synchronization issues.

The Virgo's core features offer the user full flexibility, limitless variations in label design with a smooth workflow.

The Virgo digital label finisher is truly the perfect on-demand short run label finishing solution for those using a digital color label printers and presses.

Virgo software

Virgo software works together with a camera forming an integrated optical black-mark registration system.

With this software, the operator can import the cutting files created on Adobe Illustrator, Inkscape or Corel Draw which is also used to create the black marker.

Virgo is equipped with a camera used to detect the black-mark printed on the media. This camera assist the software in detecting the black-mark created inside the cutting file.

This process tells the plotter when and where to start cutting the media.

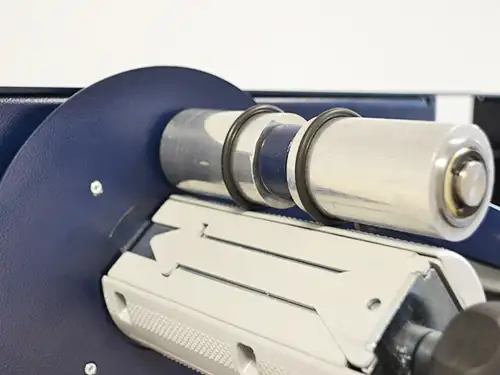

Waste pressing Roll

Thanks to the pressing roller positioned above the waste core holder facilitates the matrix removal from the die-cut roll, reducing the risk of tearing and ensuring more precise operation of the machine.

Easy to move

Virgo series are equipped with two handles, one on each side, that allows you to easily move the machine.

This added benefit makes the Virgo a complete machine for all of your business needs.

Brochure | User Manual REV.09 | User Manual REV.10 | User Manual REV.11 / REV.12 |

-

-

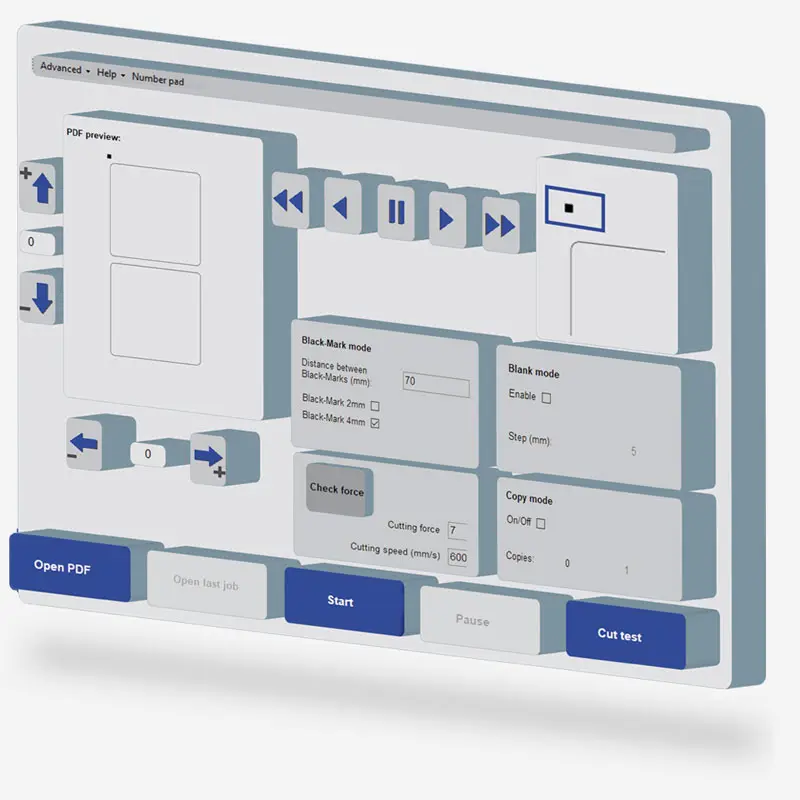

VIRGO cutting Manager

Virgo software works together with a camera forming an integrated optical black-mark registration system.

With this software, the operator can import the cutting files created on Adobe Illustrator, Inkscape or Corel Draw which is also used to create the black marker.

The camera equipped on Virgo assist the software in detecting the black-mark created inside the cutting file. This process tells the plotter when and where to start cutting the media.

-

-

From print to the finished label:

Elevate label production with our in-house, real-time finishing system.

Our Epson C6500A Printer Work Table is specifically crafted to address the pressing need for accelerated label production within your company, streamlining the entire process from printing to the final label.

-

-

Table for VIRGO

The table, an optional designed specifically for our compact VIRGO finisher, providing the operator with perfect support for the laptop connected to the unit and a great shelf to store printed or die-cut rolls.

Moreover, with its handy wheels, it can be easily moved to a new space when needed, ensuring flexibility and convenience.

-

-

Liner rewinder module

The new accessory designed to rewind the lamination’s liner will allow the use of the most modern and silent lamination rolls.

Developed as an optional, it is possible to be purchased separately and installed subsequently when it is required thanks to the predisposition on Virgo units.

| Optical Sensing | With the help of the camera, the Virgo uses an integrated optical black-mark registration system allowing it to read one black-mark for each cutting layout, optimizing cutting speed with no synchronization issues. |

| Adjustable Clutch | This feature allows for a flat tight finished roll and waste material. |

| Size Does Matter | Virgo compact size help operators have more room to easily and quickly load the media and get the machine ready to work in a few minutes. |

| Media Track | Virgo is equipped with an ultrasonic sensor system that generates a loop of media both in plotter input and output in order to guarantee a smooth media track during the cutting operations. |

| Slitter Blades | Virgo is equipped with inexpensive multi edge blades helping to extend the life of the blade. |

| Blank Labels | Cutting blank labels on the Virgo is hassle free. With the help of the Scorpio software, operators will only need to set label step, meaning there's no need to load media with a pre-printed black-marker. |

| Software | Virgo proprietary software can be installed on any computer running Windows 8.1 or later. Not supported by macOS systems. |

| Remote Assistance | Customers whose computers are connected to internet can be reached by one of our operators for remote assistance and firmware upgrades. |

| All trademarks and copyrights are the property of their respective owners. | |

|---|---|

| VRG14PL | VRG22PL | |

|---|---|---|

| Input / Output Roll Diameter | 200mm (7.87”) | 200mm (7.87”) |

| Minimum Web Width | 110mm (4.34”) | 110mm (4.34”) |

| Maximum Web Width | 140mm (5.51”) | 225mm (8.86”) |

| Maximum Cutting Width | 122mm (4.80”) | 200mm (7.87”) |

| Minimum Slitting Width | 19mm (0.75”) | |

| Minimum Label Length | 10mm (0.39”) | |

| Maximum Label Length | 350mm (13.77”) with limitations | |

| Lamination Module | YES | |

| Number of Slitting Blades | up to 6 | up to 8 |

| Maximum Media Thickness | 0.25mm (10 mil) | |

| Maximum Cutting Speed | 600mm/s (24 in/s) in all directions | |

| Roll Core Size | 76mm (3”) | |

| Agency Certifications | CE, FCC, RoHS | |

| Warranty | One Year Parts and Labor. Usage Limitation may apply | |

VIDEO